MAXWELL GLOBAL PIPING SOLUTIONS WLL

Office no 109. Blg no 2067. Galali road

Slide

Slide

Slide

Maxwell Global Piping Solutions WLL has committed significant resources to supporting this growing sector. The midstream sector, which includes gathering, transmission pipeline, and natural gas utilities, is serviced by our branch locations, distribution centers and project groups strategically located

Why choose us?

All of our products satisfies the latest International standards like ASTM / ANSI / DIN / ASME as well as client specified requirements.

The combination of these products and services has enabled us to be a leading supplier in the world, catering to a broad spectrum of industries such as Oil & Gas, Defense & Research, Hydrocarbons, Mining, Hydraulics & Pneumatics etc.Due to our high levels of inventory we are able to cater to both mega projects and contingent requirements of standard size almost immediately for dispatch

Maxwell Global Piping Solutions WLL stands out with no competition in the supply of Stainless Steel, Duplex Steel & Carbon Steel. These items have critical applications and no other company can provide the rate & delivery as low as our company with world class quality.

Other material of supply includes:

- Carbon Steel

- Stainless Steel

- Alloy Steel

- Hastelloy

- Duplex Steel

- Super Duplex

- Brass

- Cupro Nickel

- Copper Nickel

- Aluminium Bronze

- Austenitic Steel Grades

- Inconel

Dimensions & Weight

WEIGHT FORMULA

Definitions

D – Diameter in mm or inch

D1 – Small Diameter

D2 – Large Diameter

T – Wall thickness in mm or inch

L – Length in meters or feet

W – Width in meters or feet

R – Radius of bend in mm or inch

e – Angle of bend in degrees

p – Density of steel kg/m3” or lb/m3

=7850kg/m3, 0.2833 lb/m3

for austenitic stainless multiply by 1.05

for ferritic stainless multiply by 0.95

T – Thickness of concrete in mm or inch

8 – Density of concrete in kg/cubic m or lb/cubic ft

PIPE AND TUBE

Standard wall thickness with weight per meter and

per foot is listed in specifications and those for API5L

and ANSI B36.10 are included in this brochure.

For Non Standard wall thickness:

Weight kg per meter = (D-t) x t x 0.02466

Lb per foot = (D-t) x t x 10.68

Apply correction factors for austenitic and ferritic stainless

A more accurate constant of 0.02466 15 is used in EN 10208

and ISO 3183

PLATE

Weight

Weight = volume x density

Weight in kg = L x W x t x 7.850 kg/m3

Weight in lb = L x W x t x 40.80 lb/in3

Apply correction factors for austenitic and ferritic stainless

CONES

The weight of a cone can be calculated from the large

and small diameters D1 and D2, the length of the

cone L and thickness of the plate t.

Weight = L x t x (D1+D2)/2 x 0.02466 kg

Weight=Lxtx(D1+D2)/2 x 10.68 lbs

VALVES

Weights must be obtained by the manufacture of the

particular valve design

BENDS

Length of bend = O x R x1.746 10-5 m

= O x R x 1.455 10-5ft

Weight of bend = Length of bend x weight per meter

(foot) of pipe.The radius of the bend R is usually given

in terms of the pipe diameter, for example R=5D

CONCRETE COATED OR LINED PIPE

Given here is the weight per metre or per

foot of concrete coating or lining.

Remember to add the weight of the steel pipe

Coating weight per m = 8 x (D+T) T x 0.000003142

Coating weight per ft = 8 x (D+T) T x 0.02182

Lining weight per m = 8 x (D-2t -T) T x 0.000003142

Lining weight per ft = 8 x (D-2t-T) T x 0.02182

The density of concrete depends on the specification.

190 lb/cubic ft (3050 kg/m3) are a common density

Density in lb/ft3 x 16.05 = Density in kg/m3

Ie. 145 lb/ft3 = 2327 kg/m3

Quality Assurance

Maxwell Global Piping Solutions WLL adopts an international practice of implementing and adhering to a quality assurance system (i.e. process based on system) & has been certified to ISO-9001-2015. Moreover, periodic checks are put in place to ensure the system is adhered to line with the lates quality trends, emphasizing on customer needs and customer satisfactions at relevant levels. We always looks forward in enhancing customer satisfactory by value added services and continual improvement. We also provide technical documentation and final data dossiers in the contractual language to complete the supply. Documentation supply depending on client request may consist of,

- *Project Specific Quality Plan

- *Inspection & Test Plan

- *Manufacturing and testing Procedures

- *Welding Procedure Specifications (WPS)

- *Procedure Qualification Record (PQR) & relevan WPQ

- *NDT procedure and reports

- *Material test certificates to DIN 50049 or EN 10204 type: 2.1, 2.2, 2.3, 3.1, 3.2, (3.1b. 3.1c) according to clints

requirements. Each QC dossier is supplied with number of copies stipulated in the contract

Dimensions & Weight

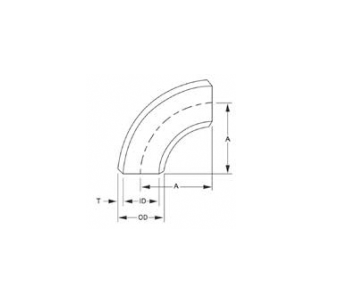

AW = 3.8699 x A x T x (OD-T) x 10-5

AW: Approx Weight (Unit:kgs)

T: Wall Thickness (mm)

OD: Outside Diameter (mm)

A: Radius (mm)

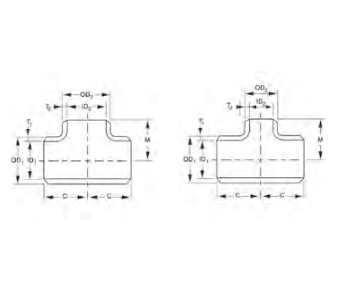

TEE

AW = 2.4649 (2CT1(OD1-T) +

T2(OD2-T2)(M-OD) x 10-5

T1: wall thickness (mm)

OD1: Outside Diameter (mm)

T2: wall thickness(mm)

OD2: Outside Diameter (mm)

C: Centre to End Diameter (mm)

M: Center to End Diameter (mm)

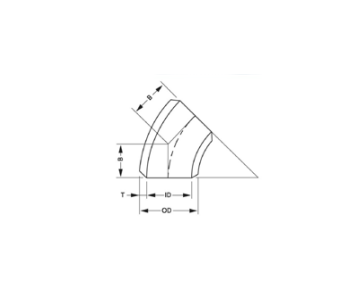

AW = 1.9350 x A x T x (OD-T) x 10-5

AW: Approx Weight (Unit:kgs)

T: Wall Thickness (mm)

OD: Outside Diameter (mm)

A: Radius (mm)

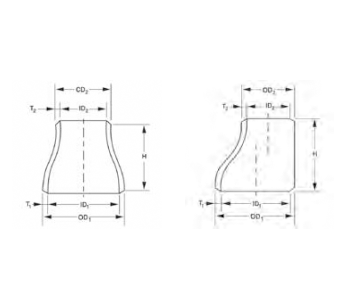

REDUCER

AW = 2.4649 x H x T x

(OD1 + OD2-T) x 105

AW: Approx Weight (Unit:kgs)

T1: Wall Thickness (mm)

OD1: Outside Diameter (mm)

OD2: Outside Diameter (mm)

H: Length (mm)

We provide the most reliable materials management solution on every project, regardless of size. By combining our capabilities, we increase our value to you.

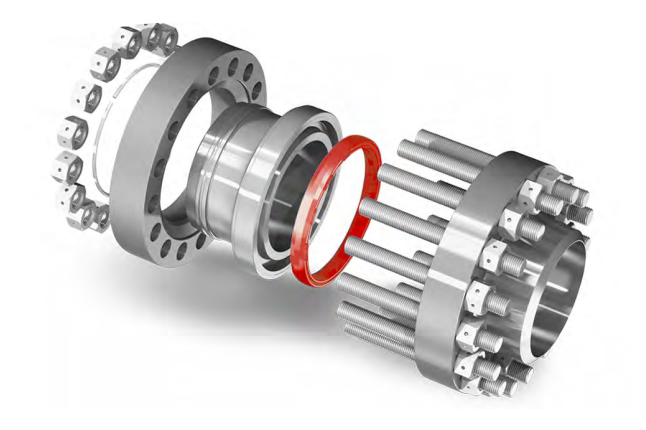

Together with our strategic partners across the globe, we distribute Pipes, Flanges, Fittings, Valves, Gaskets, and Stud Bolts in all steels and special alloys to various industries globally.

Our dexterity lies in our extensive knowledge of manufacturer’s capabilities, which is an essential element when it comes to projects and their time constraints. Therefore, GPS works with world class stockiest & supplier that meet and surpass all the latest quality and approval norms. We choose our manufacturers based on their ability to meet specific contractual requirements, in particular their product speciality, technical compliance, quality and delivery performance.

Big or Small, Simple or complex, our business systems and processes seamlessly integrates sourcing and procurement, quality control, warehousing and logistics providing complete transparency to monitor the status of the material order from start to finish.

Our sales team are adept in understanding the technical and commercial needs of a client and in proposing suitable materials. Based on the needs of a project in terms of cost and delivery, they are proficient in proposing substitute/alternative products that attune to project norms

Our procurement and technical teams regularly visit and audit the facilities of our mills in order to bring to our clients innovative and quality products at the most competitive prices.

Maxwell Global Piping Solutions WLL believes in professionalism when approaching customer needs. Care has been taken to ensure our clientele get value added services including, but not limited to, technical documentation/records/material testing as part of relevant material specification or special requirements.

Maxwell Global Piping Solutions WLL – a specialist global supplier of world class piping products together with turn-key services & solutions, project supply management and consultancy [Read More]

Contact Us

Office no 109. Blg no 2067. Galali road number : 5541. Complex/Block 255. Behind Galali petrol station. Bahrain.

00973-33928402

projects@maxwell-piping.com